New product development projects, often referred to as NPD projects, often miss out on these six important corner stones for securing great end results. The results are all too often a disappointment. Use these six leadership tips to reduce the risks in your new development project!

I have participated in many projects developing new products, sometimes as a member, a reference person, project leader, project owner or member of the steering group. Many of these projects have failed to meet expectations and I have learned that you can apply these six golden rules in order to increase your chances of success in the end.

#1 Don’t make it a pure technology project!

Sometimes cool and advanced products come out of research and development departments. This is great, but when it has become a technical project which is developed by engineers to satisfy their wish for pushing technology forward you are in danger. In these cases, other functions often become secondary and must react to the finalized product rather than being a part in shaping it. New product development projects that are only about the engineers´ lust for technology or what they “know is best for the customer” often turn out to be difficult to sell, difficult to manufacture and unnecessarily expensive.

This might end up with very few units being sold in the end, and the development costs per unit will be high. Exploratory research is of course very much needed, but it should be done on purpose and not when the aim is to develop a new product. As a business leader, you need to ensure that the outcome of the NPD meets customer expectations and can be commercialized.

#2 Perform a proper Pre-study

Have a proper pre-study before pursuing your NPD project. Often, a great idea goes into project mode too fast with explanations such as: “This has to be good!”, “We need to move before competition does!”, “This is a no-brainer!” etc. Even if that is the case, there is no excuse to skip a proper pre-study.

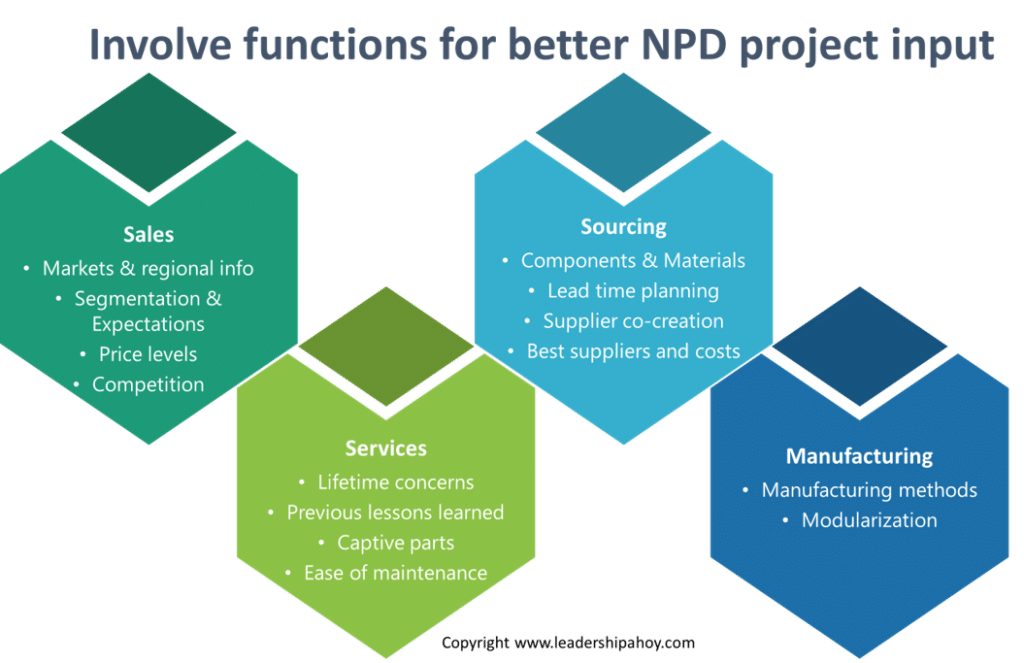

The pre-study should involve all functions necessary to develop the product, but also to build the product and bring it to market. Please note that this is NOT limited to engineer and R&D functions. You should really work hard to involve product management, sales, sourcing, manufacturing and your service organizations into the pre-study phase. With joint experience, they can provide multiple perspective and input on what to develop, when and how to develop it, which customers would want the product, how and where to manufacture it and what components and raw materials to use. This will increase the chances of proper manufacturability, usability, commercialization and after sales life cycle of your new product.

#3 Engage the customer before you start your NPD project!

Involve the customer already in your pre-study! Talk to customers and find out if your idea can solve a need or simply to find out more about the general needs the customers have. Besides figuring out what to develop, the dialogue with the customer can also hint on the price point of your future product as in: “How much would it be worth to the customer to solve this need/problem?”. You would also learn more about potential restrictions technically as well as commercially – both important input areas for your NPD project. All the information you obtain from customers should be fed into your pre-study and help shape the scope of the NPD project as well as the business case for the future product.

#4 As a leader, you must ensure there is a Business Case

Develop a sturdy business case for your project before any real investments start. Information for the business case can be gathered and analyzed during the pre-study together with reasonable assumptions and risk assessments for instance. The business case should at minimum be a basis for deciding whether to move forward and invest in the NPD project or not. As a leader, you need to make sure that the business contains for your NPD project contains at least the following:

- Scope of the NPD project

- Which functions should be involved and to what extent and in what parts of the scope?

- Resource estimation and total costs in work hours and money. You might also want to include lost profit if the resources you plan to use need to be pulled from profitable on-going tasks

- Risk assessment: what can go wrong with this new product development project and what would the consequences be?

- End state: what is the concrete outcome of the NPD project. This should be described in multiple aspects, not just “Product X”. It should be more like Product X at selling price Y, cost price Z, lead time A for customer segment B with futures 1-10.. These parts will be impossible to respond to properly without involving many functions and having a cross functional, collaborative pre-study

- Financial conclusions on costs, projected income, cannibalization on existing products, cash flow, return on investment etc. so you know whether this will be profitable or not

The business case also defines the expected outcome and can be used to measure the future project deliverables against. A truly successful NPD project meets or exceeds all these expectations.

#5 Involve all applicable functions in your organization as early as possible!

I have seen products delivered from the R&D department in terms of a bill of material and a complete set of drawings. This package is then sent to the factory and the purchasing department with the order to start producing since the prototype has already been launched at a recent trade show. The expectations and the reactions now become like the following examples and perhaps worse, due to lack of proper leadership essentially:

- Sales should sell the product! Sales often wonder: where is the product information, technical specs, promotion materials, price, lead time and other vital information.

- Operations/factories should manufacture the product. First unit should preferably ship yesterday since an early adopter has already ordered one. Operations go into panic mode and must set manufacturing methods very fast, often resulting in poor optimization, high costs and quality risks.

- Purchasing/sourcing should buy the components and material fast so the factory can start manufacturing! Purchasing and sourcing are now in a rush and lose both time and leverage when it comes to negotiating with suppliers. Instead, high prices are established and inherited for future production, setting high anchor levels for the cost prices.

- Services should stock spare parts and have the manual ready yesterday! Services wonder which parts will be wear and tear, ask why no parts have been made captive and ask for maintenance intervals for the manual. The quality of the manual is at risk and preparing opportunities for after sales revenue and good warranty handling is jeopardized.

Let us look at the opposite situation that can become a reality if you really make sure that all necessary functions are involved from the beginning. The following are just some good examples, there are even more reasons to ensure cross functional collaboration and good leadership in NPD projects

- Talk to your sales department to find out more about restrictions in the marketplace, regional requirements, customer segmentation and expectation. Sales could most likely provide more information on price levels of competitors as well as performance of competing products. That way you increase the chance of your product becoming a hit with improved market shares as a result.

- Your service department can elaborate on previous mistakes and product lifetime concerns. They might know of previous product feedback that can now be utilized to increase customer satisfaction of the new product to a new and higher level. Furthermore, they could advice on which parts should be made captive and how to design the product for the optimum maintenance and spare parts plan resulting in future income for you and your company. The latter will also secure that your product works well and for a long time resulting in higher customer satisfaction and higher chances that they will buy again.

- Sourcing can suggest on components and materials for which they know they can leverage their negotiations. They can comment on special components with long lead times that should be avoided. If sourcing takes their job to the next level, they might even know of truly new and innovative ideas among suppliers that can lead to co-creation or help push the technology level of your final product to an even higher level. Sourcing should be involved in the entire project and be given ample time to find the best suppliers and negotiate favorable prices and terms.

- Manufacturing can comment on what methods that are better and more cost efficient to use and specific things to avoid. Perhaps some welding joints should be removed by design? Perhaps a modularized approach can enable using the same stocks for multiple products? There is a wealth of knowledge within manufacturing, make sure this is part of shaping the scope and expectations and that manufacturing representatives take part in the new product development project.

- All the functions above will feel more motivated and more accountable to get the product to work in the end. If they aren’t involved, they can easily blame any problems on the project group not hearing them out before hand. For example, a salesperson could say that the product is impossible to sell and that they could have told you that from the beginning..

#6 Perform field tests or partial field tests

If you want to reduce risks and reduce the number of bad surprises, you should test your product thoroughly before offering it to a wider market. This can be done in many ways depending on the type of product you are developing. I will elaborate on a physical product consisting of many different sub parts in this segment.

If time and circumstances permit, do a field test of your product to “get some hours” on it basically. Depending on the product, this might need to go on for weeks, months or even longer. This will likely show any unforeseen problems or teething issues quickly. Perhaps you can simulate wear and tear over the years by repeated mechanical movement, shake tables or similar in order to understand when it breaks as well as how it breaks. If not, then your structural calculations and engineering design work could cover the basis. These days there is very advanced software available for modeling fatigue and other problems.

When time is of essence, perhaps you can start testing some sub systems earlier in order to save time? Let us say you are developing a new car and you already know which tires you are going to use. Perhaps you can put those tires on an already existing car so they can be out on the roads and get tested while you are designing the new car. This way you might have test data for the tires collected over the 12 months remaining in the development project and some aging conclusions on them can already be drawn before the end of the NPD project. If your tire choice is wrong, it’s better to know before you launch the product than after, right?

Doing a pre series for field tests also enable the delivery functions, such as sourcing, manufacturing and services to gain experience by trial and error. Perhaps there is still time enough to make some adaptions to the product based on what manufacturing found out when they built the first five units?

Do you have any experience to share? Perhaps you have a seventh golden rule for leadership to consider in NPD projects? Please comment below.